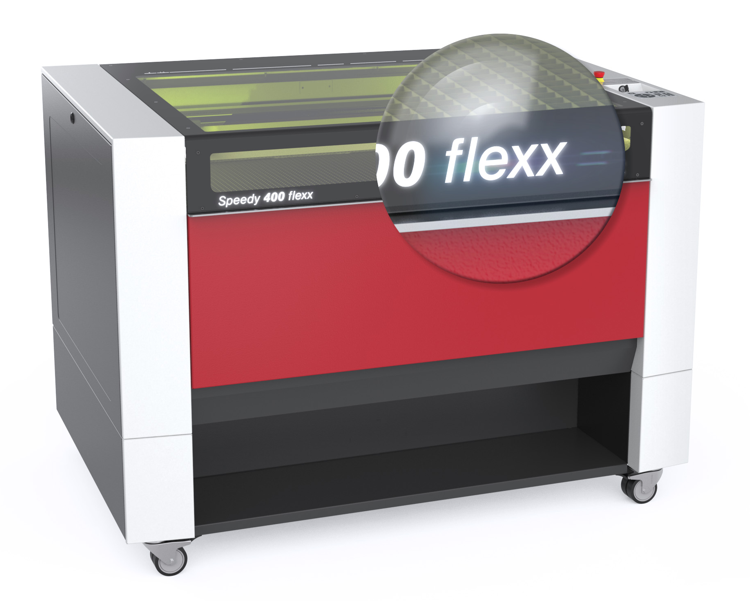

Laser engraver sets new standards for flexibility

Trotec has introduced the Speedy 400 laser cutter. Designed to maximise productivity, it features optimised performance for quality and speed, easy material loading, maximum operator comfort and efficient processing.

To improve production efficiency, the maximum engraving speed of the Speedy 400 has been increased from 3.55 m/sec to 4.3 m/sec at an acceleration of 5g, which when combined with the motion planning system OptiMotion, make this “the fastest mid-size laser engraver on the market”, capable of cutting up to eight times as fast as comparable laser cutters.

OptiMotion calculates cutting speed and acceleration based on the geometries of the graphic in real time, allowing you to easily plan your production time per job.

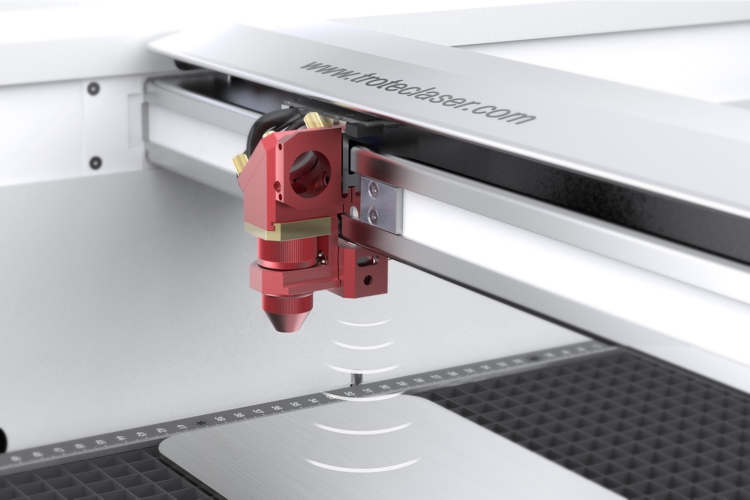

Even when processing at the maximum working speed, the Speedy 400 is said to easily achieve perfect results thanks to highly intelligent control electronics, precise mechanics, reliable laser sources and the intuitive Trotec JobControl software.To reduce pre-production time, Trotec’s patented Sonar Technology is a standard feature. This system automatically detects the focus point at each position of the worktable and moves to the correct focus position. This ergonomically redesigned machine offers maximum comfort for operators, with the front lid handling design making loading materials easier. The progress of individual jobs can be easily seen at a glance via a dynamic status display. Previously, job times have only been visible in the laser software but this feature gives users an easy way to see at a glance whether the laser is operating, a job is completed or stopped, the laser source and other statuses.

The 400 is available with a CO2 laser source or with Trotec’s patented flexx technology, featuring both a CO2 and fiber laser in one machine.

Combining both laser sources into a single machine allows multiple materials to be processed in a single job with no requirement for changing the lens, laser source or focus.