The largest Zinc Engraving Facility in Europe

Photocast Products Ltd started life in 1988 from the corner of a rented warehouse with a small zinc etching plant, an assortment of bench tools, and a small paint booth. According to the company’s Director, Pauline Hill, the main style of business at this time was the production of machine ID/nameplates and labels as well as small painted plaques. “Whilst we still have a large involvement with these items it was the development and our involvement with the zinc photoengraving process that has enabled us to produce deep etched plates while retaining highly accurate detail that has escalated our business and continues to dazzle.”

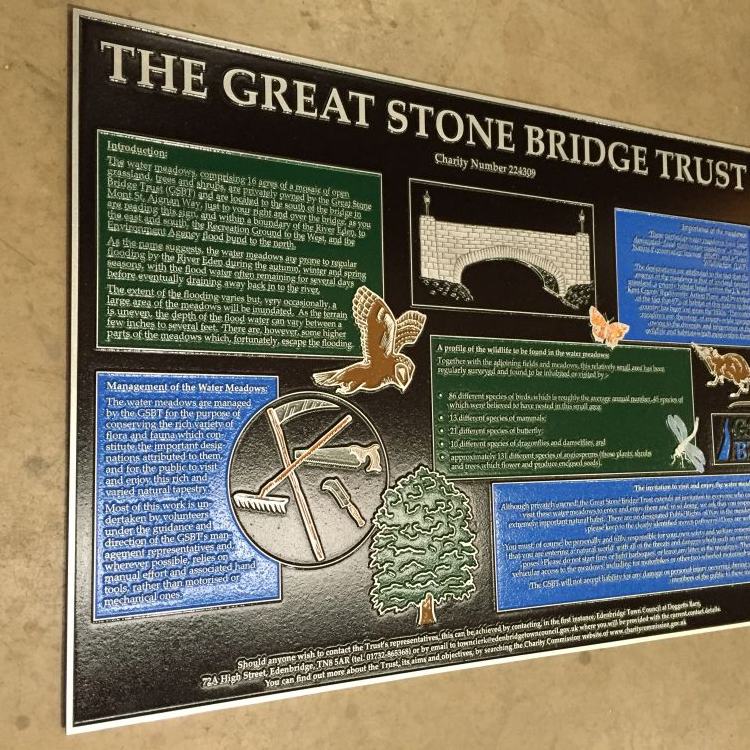

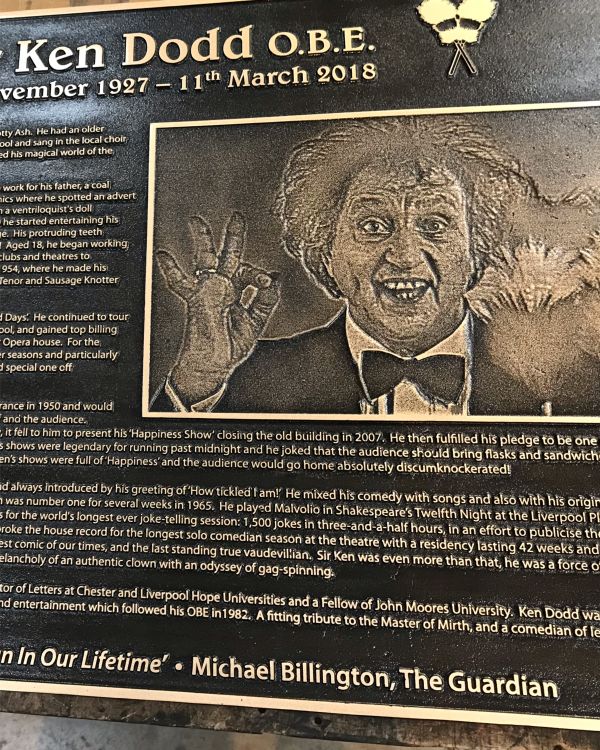

There is a phrase often used in photoengraving ‘if you can draw it, we can etch it’. That certainly rings true with all the plaques and panels produced at Photocast, which is all achievable thanks to their highly skilled in-house team of image manipulation artists.

Pauline explains, “Our business growth was dependent on the size and scale of our etched plate production and all of the associated techniques. Investment in three 210 litre etch baths, large format paint and finishing equipment, together with embracing all of the latest artwork and film production hardware and software enabled us to produce ever larger and more detailed plaques and paneIs.

To facilitate all these developments, Photocast also had to move to new purpose built 6500 sq. ft. premises. “This move has allowed us to have continued developing our etching and finishing techniques and broaden our product range. This has led inevitably to an increased and more varied customer base,” she says.

Pauline continues, “From our original plaques and labels work we moved into golf signage and large interpretive panels, blue plaque schemes, personal and memorial plaques and dedications as well as a newly created product range of donor or dedication walls and panels.”

Magnesium etching

Photocast also invested in a new Magnesium etching plant. This enables the company to deep etch tooling plates for several interesting industries. “We use deep etched magnesium plates for detailed casting patterns that we send to our foundry for traditional sand casting. We then finish the castings on site in Liverpool. We also moved into the printing world and created a new company call ‘The Blockshop’, which uses all our in-house capabilities to produce letterpress printing plates, hot foil stamping blocks and embossing and debossing stamping tools. This is a great addition to our product range and a stand-out company in a shrinking market,” says Pol.

Acquisition leads to greater capabilities

Further developments for Photocast were made in March 2020 when long time business friends Charles H Coward Ltd of Sheffield acquired Photocast. CHC Group Sales Director Chris Hogan explains, “We had worked with Photocast for the production of their bronze and aluminium sand casting of plaques for over eight years and when the opportunity came up to take over the ownership of the business and offer all of our full capacities and experience in metal technologies seemed the right thing to do. It was immediately clear to all involved at Photocast that we had squared the circle to become, perhaps, the only group that now has the skills to create cast products from conception to completion.”

Hogan continues, “With adding our foundry facilities to the Photocast armoury we can also push the casting boundaries even further. After much development work we now have the ability to combine etched patterns with CNC sections to create a range of bas relief plaques, which enabled Photocast to compete with the much more labour intense and costly fine arts casting.”

Photocast’s customer base continues to grow from individuals and small sign outlets to some of the largest organisations in the UK and Europe. “We have been involved in projects for The National Trust, English Heritage, The British Legion, The War Graves Commission, The Plymouth Mayflower 400 year project along with Liverpool and Arsenal Football Clubs,” he says.

Chris Hogan concludes, “As our technical skills evolve, we are always looking to develop new and innovative products as well as working alongside our customers and partners to achieve attractive, practical and fine art pieces.”