New transfer technology for garment printing

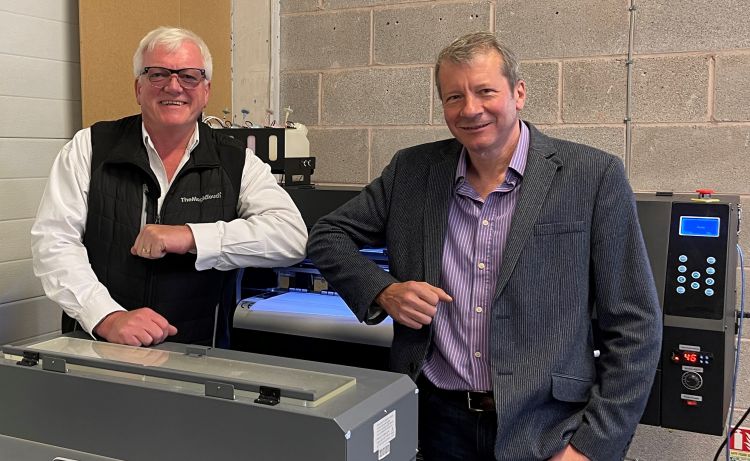

TheMagicTouch and Resolute DTG in the UK announce their collaboration with the joint introduction of the latest in digital image transfer innovation. Both companies for the past 6 months have conducted an extensive evaluation of all things relating to the new DTF (Direct to Film) transfer technology.

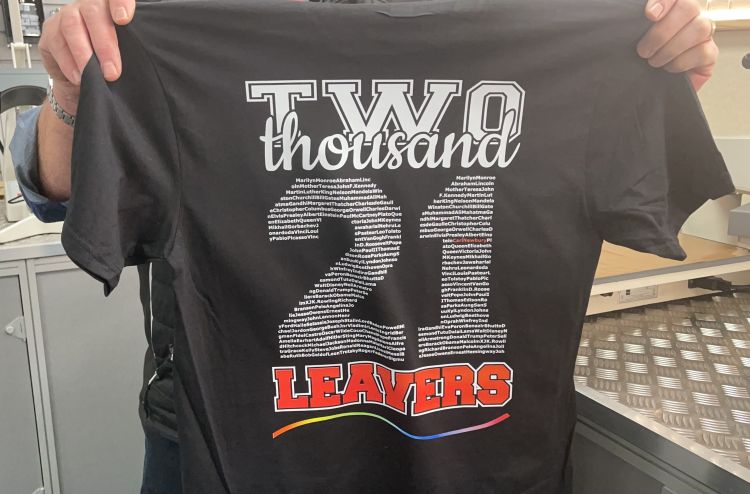

Having the ability to produce short and long-run full colour transfers for garments and textiles, regardless of colour or composition and being compatible with cotton, polyester, leather, softshell, performance fabrics, pique blends, canvas, denim and much more, is a must for all garment decorators to consider.

The new process is simple; firstly print the roll-fed 60cm wide coated PET film using a special pigment based textile ink and then lightly coat the printed transfer with a unique hot-melt adhesive powder. The transfer is then cured using either the automatic “Shake&Bake” roll fed unit, heat press or traditional dryer. The cured transfer can then be applied immediately to the garment/product using a traditional heat press. Please note there is no pre-treatment required to the garments.

The flagship printer for DTF is the new R-Jet Pro DTF printer featuring the latest in dual print head technology 2 x 8 channel industrial print heads (2 x CMYK) & (8 x W) and powered using the latest version of Resolute RIP PRO software to ensure control and colour management. Amongst its many features the printer includes the “Ink mixing” function to ensure the perfect circulation of the white ink resulting in minimal maintenance or production issues. The wet cap system allows the printer to be switched off for periods of up to one month without the need to flush out the white ink.

For those looking for an affordable and reliable alternative to DTG, but prefer the look and feel of textile inks, then the DTF technology is exactly what you are looking for. This new technology “Bridges the Gap” between DTG, screen printing and the traditional transfer printing methods.

The finished transfers offer outstanding durability, stretchable and incredible feel and vibrant colours.

Jim Nicol Managing Director of TheMagicTouch commented, “We have previously opted away from DTG for various reasons and indeed passed any enquiry directly to Colin and his team at Resolute, but the DTF process is simply the best new transfer solution for many, many years. With our transfer experience combined with Resolute’s knowledge and experience with DTG we believe we have the perfect combination to market and more importantly support this product beyond customer expectations. This really is a game changer for this industry”.

DTF offers more flexibility with the transfers. Printed transfers can be forwarded elsewhere to be applied at a later date with a shelf-life of over 2 years, thus creating another potential revenue stream for the user.

Both TheMagicTouch and Resolute supply the printers and powder units together with the inks, PET film, and consumables, all supported with the highest standard of technical and marketing support.

For further details, samples or to arrange a demonstration contact sales@themagictouch.co.uk or sales@resoluteink.co.uk