Chemical etching - How do they do that?

Chemical etching may use some complicated processes but the principle is quite simple. It is also known as chemical engraving, and like engraving it involves making holes in bits of metal, and then usually putting paint in the holes. The only difference is that the hole is dug into the metal using acids instead of metal tools, and being a photographic process, much finer detail can be achieved.

Chemical etching may use some complicated processes but the principle is quite simple. It is also known as chemical engraving, and like engraving it involves making holes in bits of metal, and then usually putting paint in the holes. The only difference is that the hole is dug into the metal using acids instead of metal tools, and being a photographic process, much finer detail can be achieved.

To get started you need some artwork. All our artwork is sent to us from customers by email, all we do is give it a good check over and add some cut marks, then produce an actual size film from the artwork using our imagesetter.

Meanwhile, a piece of the required metal, usually stainless steel or brass, is cut from stock, inspected & cleaned. It is then dipped into a light sensitive paint called a photoresist - photo because it is a photographic material, resist because it is resistant to acids. Simple.

After being stoved in an oven at a precise temperature, the coated piece of metal meets the film in an exposure frame. The film is held on top of the coated metal by a vacuum and exposed to ultra violet light. The coated metal is then immersed into a developer, which removes photoresist, leaving an exact copy of the image on the surface of the metal. This is carefully inspected for any faults, and this is the stage when we find most of our customer's speeling mistakes.

After being stoved in an oven at a precise temperature, the coated piece of metal meets the film in an exposure frame. The film is held on top of the coated metal by a vacuum and exposed to ultra violet light. The coated metal is then immersed into a developer, which removes photoresist, leaving an exact copy of the image on the surface of the metal. This is carefully inspected for any faults, and this is the stage when we find most of our customer's speeling mistakes.

Most other etchers screenprint a thick ink to reach this stage but the principle is the same, bare metal ready to be etched - the metal you don't want to be etched is protected. We use photoresist as the quality and definition are much better and it enables us to do some very creative things. To give you an idea, we reproduced the Lord's Prayer in beautiful Times Roman text on a piece of stainless steel 10mm x 6mm. That was just showing off but the same principle allows us to etch very fine half tones, very useful for reproducing photographs and graduated tones in designs. It is also much quicker and speed is everything in the sign trade.

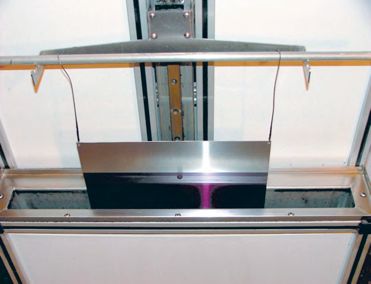

The metal is then taken to the etching room, which is always expected to be the exciting part but is actually the most simple. The metal is sprayed with acid in a machine at a very carefully controlled temperature and for a precise time. Easy as that.

The metal is then taken to the etching room, which is always expected to be the exciting part but is actually the most simple. The metal is sprayed with acid in a machine at a very carefully controlled temperature and for a precise time. Easy as that.

The acid is not some fuming cauldron of life threatening evil such as you would find in a James Bond film, it is all quite boring - you can even etch copper using vinegar. All the clever stuff is involved in making the image before etching and what you do with the metal now that you have made holes in it.

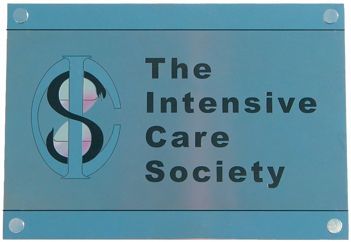

Most signs need just a bit of colour putting in the etched design to finish them off and that usually means paint. We are clever bunnies and use the etching mask to get the paint only in the etched bits, but we can be even more clever than that. The paint is usually sprayed on so we can airbrush coloured highlights, blend colours into each other, even have colours touching by using all sorts of clever masking techniques. This is usually the stage where the most creative work is done, all without touching the surface of the metal, so a beautiful mirror polish remains perfect.

All that remains is to trim the sign on a guillotine, drill some holes if required and following a final inspection send it off to the customer. Brass signs can be lacquered and once again we can show what clever bunnies we are by such things as combining mirror polish and satin to make very striking designs.

All that remains is to trim the sign on a guillotine, drill some holes if required and following a final inspection send it off to the customer. Brass signs can be lacquered and once again we can show what clever bunnies we are by such things as combining mirror polish and satin to make very striking designs.

That in a nutshell is the etching process. There is some very clever chemistry involved, a lot of the techniques are quite complicated, but it is basically making holes in bits of metal and filling them with paint, all very simple.

For further information contact Multitechnic on Tel: 01670 512090 or visit www.Multitechnic.co.uk