Using your router to help fight COVID-19

Most of the world is currently battling the COVID 19 pandemic and many countries are in the midst of a total or partial lockdown. Most non-essential manufacturing facilities have temporarily closed in compliance with the guidelines. However, companies around the world are still doing what they can to help stop this terrible virus which has tragically claimed many, many lives in recent weeks. Most companies have found the switchover of producing signs, plastic point of sale and engineering components, to the manufacturing of protective equipment, a seamless transition.

The demand for protective barriers and equipment has increased dramatically over the last couple of weeks with some companies now running 24 hours a day. So what can be done with your router to help?

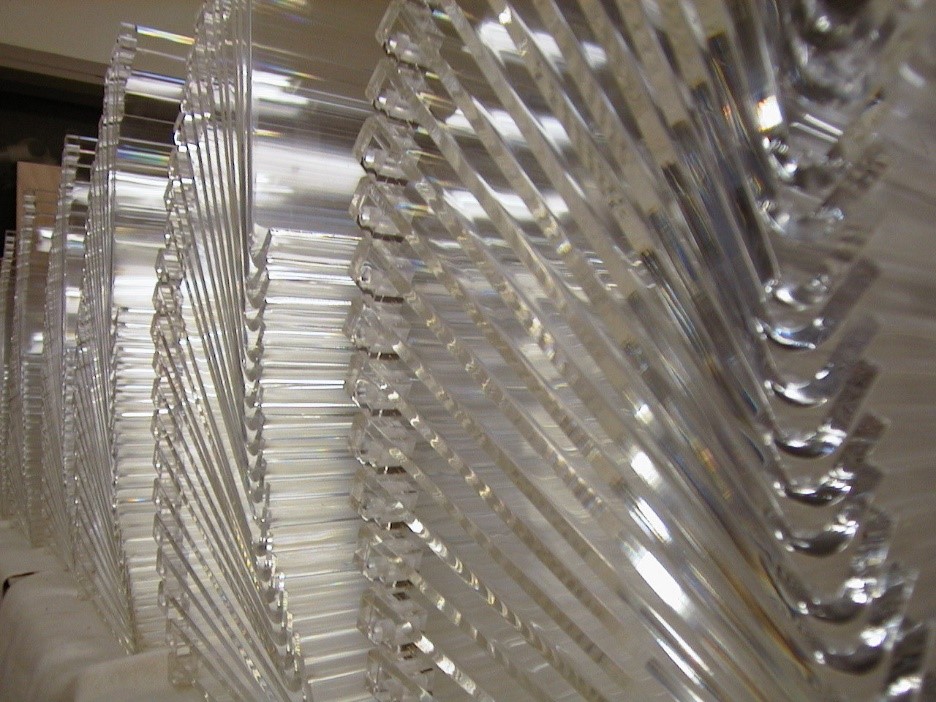

Shops and supermarkets are requiring urgent measures to protect their customers and staff. Screens dividing the customer from the staff members can be easily cut and shaped out of clear acrylic and polycarbonate. These can be routed very easily on a CNC router at high speeds. A single fluted up cut tool should be used to allow for a high quality of cut and finish. In some cases, a matt finish is required on the cut edge and therefore adjustments can be made on the speed of cut to accommodate this.

Clear plastic face masks are in urgent and constant demand. The front section of the mask is usually cut from very thin polycarbonate plastic sheet. This is usually 0.5mm or less, to allow for shaping around the mounting frame. A single fluted down cut routing tool is required to cut this thin material on a router. The thin material will lift during cutting if an up cut tool is used. The down cut tool pushes the material down during routing, assisting the vacuum hold down and preventing lift.

Thicker, free standing customer dividers and barriers can be manufactured out of materials such as foam PVC or acrylic. This would normally be 10mm or thicker. A single fluted up cut tool would be the correct choice for either of these materials, with the option for polished or matt finish as required.

For more industrial applications such as routing components for ventilators, incubators and other medical equipment, dry cut tooling is available for high speed machining of aluminium on a standard CNC router. This can be done without coolant and requires no cleaning up of the machine or components after cutting. Engineering grade plastics can also be machined with ease, using the up cut tools, providing accuracy and high cut quality. Machines which are normally only used for general plastics, wood and foams can now be used to cut harder materials without the fear of cross contamination of liquids.

The Crown Norge range of routing tools, available from LKH tools in the UK, allows for all of these materials to be cut on a single machine. The tool length of cut is matched to the correct material thickness allowing for higher speeds and increased tool longevity. This is due to the strength of the tool not being any longer than it needs to be.

All the tools in the range have been manufactured under strict quality control measures which ensures consistency throughout. Manufactured in Switzerland with the latest grinding machinery, each tool is produced by experienced operators to the highest exacting standards, using the best European tungsten carbide available.

The geometries of the tools have been developed over many years of market research and simply listening to machine operators. The tools in each range have been developed to match to each of the common material thicknesses and diameters, which are appropriate for the task. The angle, length of cut, shank length and diameters have been developed in laboratory conditions and then rigorously tested at live manufacturing sites over many years to find the optimum balance of strength, longevity, speed and quality of cut.

We can all do our part to help to meet this challenge. The Crown Norge range of tools, supplied in the UK by LKH Tools, can help you meet this challenge.

For more information, please contact Liam Hodson at LKH Tools on 01623 401174, enquiry@lkhtools.co.uk.