Not all dots are created equal

Matt Manteit International Sales Manager at Neschen Coating GmbH, explains how innovative dot-adhesive technology is at the core of quick and easy installation of promotional graphics.

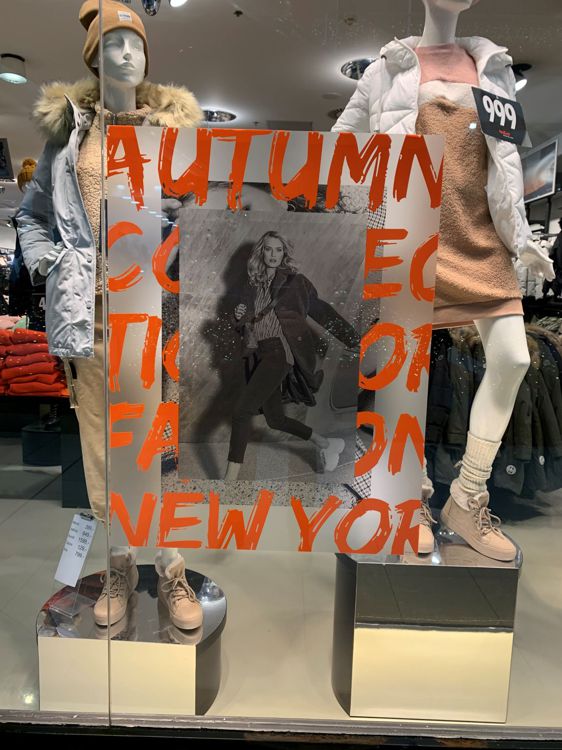

A large retail chain announces an upcoming Christmas promotion, and the supporting graphics need to be installed in over 1000 stores on windows, walls and floors. However due to time and cost constraints, it is not possible to hire professional installers for many of the stores, so who will install the graphics? Is it realistic to expect shop assistants to apply the graphics and achieve the same professional result?

The consequences are often seen in stores all over the world: decals with unsightly bubbles, creases and curled edges that cheapen and distract from the core marketing message. However, a solution exists. The solution is a material that is often overlooked because of price, but that ultimately saves time and money. A material which is so quick and easy to apply that even inexperienced, first-time users can achieve professional results. Enter dot-shaped adhesives.

What is the point of using dot-shaped adhesive?

Self-adhesive printing materials with a dot-shaped adhesive are extremely quick and easy to apply, by hand, without specialist tools or training.

Commonly, air becomes trapped under standard, full surface self-adhesive films during installation and these pockets of air can be difficult and time consuming to remove, especially for the untrained applicator. In some cases, in an effort to remove bubbles, a decal can be damaged and require replacement.

This is not the case with dot adhesives. During installation, any air naturally flows out effortlessly through the channels between the dots as pressure is applied to the film. Troublesome air bubbles do not even have the chance to form. Accordingly, professional results are extremely easy to achieve, even by store staff who may typically be more at home serving their customers rather than installing graphics.

The devil is in the detail.

The size, positioning and distribution of the dots is critical for air removal, adhesive performance and reduced visibility of the dots on the final graphic. Air can be trapped, and issues might arise if the dots are too large or too small, too close together or too far apart, or not uniformly distributed.

Often overlooked but equally important is the liner. A high quality, double side PE liner is critical for stability and trouble-free print performance. Cheaper alternatives use lower quality kraft liners, which are highly sensitive to heat or moisture and can result in costly print head strikes and tunnelling in the liner.

Choose wisely; install easily.

As with many things in life, it is often more cost and time-efficient to do your research and invest in the right graphics solution for the right application from the outset. Especially when the graphic might well need to be installed by a relative novice.

Fortunately, there are solutions such as Neschen Easy Dot® which make graphics easy to install, reposition and remove and are readily available to help with your short-term festive season graphics campaigns on windows, walls and floors.

About Neschen Easy Dot

With an innovative dot adhesive technology, Neschen Easy Dot delivers best in class stability before, during and after printing and guarantees bubble-free application. It is faster and easier to install and reposition than standard and "air-flow" adhesives and ensures residue-free removal. It is the perfect solution for short-term campaigns on windows, walls and floors.

Additionally, the Neschen Easy Dot® family has recently gone PVC-free with the arrival of a suite of new products to meet the long-term trends of sustainability and health and wellness. This range of PP or PET films have solvent-free, easy dot® adhesive technology and is printable on a diverse range of platforms including large format Latex, UV and water-based to small format HP Indigo and dry toner.