Third Veloblade investment for FPL Signs

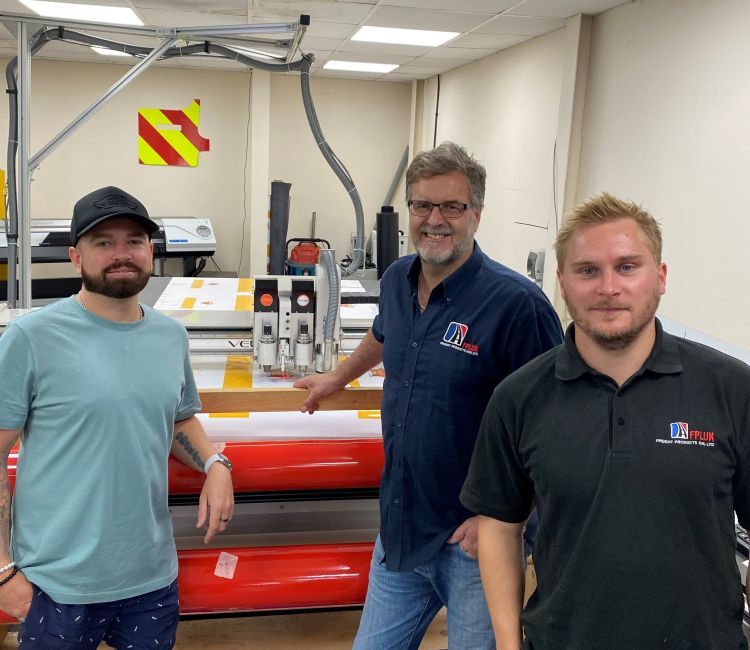

FPL Signs recently invested in a new VeloBlade Nexus wide format digital die cutting system from Vivid Laminating Technologies.

Based in Farnborough, Hampshire, FPL Signs are experts in the signage and print graphics industry. The company offer services from building signage and vehicle graphics to company wall art and branded office supplies. FPL Signs recently took the decision to install a VeloBlade Nexus to expand their signs-related cutting and routing capabilities. Particularly with wide format substrates including vinyl, Foamex, ACM and acrylic.

Nick Brooks, Operations Manager at FPL Signs said: “We decided to install Vivid’s VeloBlade Nexus wide format digital die cutting system due to its functionality, versatility and because of the existing Vivid equipment already in use within the group. FPL Signs are part of the Sandhurst Autoprint Group of Companies and the company have previously invested in a VeloBlade Volta and Nexus digital die cutting system from Vivid. So, we felt confident using the system and the fact that the Nexus came in at a cost-effective price point made sense for us to invest in.”

Brooks added, “This new investment will enable us to expand our range of bespoke signs that we can now produce in-house such as ACM tray signs, acrylic lettering and panels. We are using numerous vinyls, such as cast, monomeric, printed and kiss-cut. Our most used material is a 7-year polymeric vinyl complete with over laminating.”

FPL Signs are extremely pleased with their recently installed VeloBlade Nexus and with the quality of service received from Vivid. “Vivid’s service engineer Matt Milnes is extremely efficient in his workings and along with the technical support team we are working towards advanced use of the VeloBlade Nexus’s capabilities. Including cutting, kiss-cutting and CNC routing of various substrates such as Correx, ACM & acrylic.”

“With practice and with the help of Vivid’s technical team we will be able to maximize the use of the system to its full potential. The level of service received from the initial scoping, surveying, supply, delivery, installation, commissioning, training and support provided by Vivid have all been excellent,” Brooks concluded.