Choosing mechanical locator fixings for installing flat cut letters

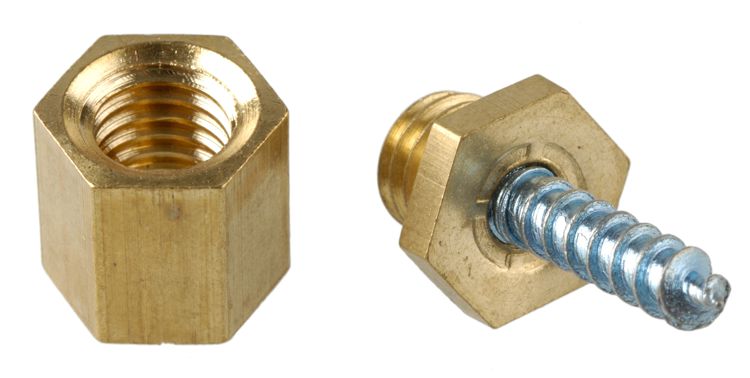

Medium brass locator fixing with fixed woodscrew - for wooden letters and fitments with wooden backing.

.

Your finished flat cut letters will need attaching to their destination whether a fascia, wall or shop front and there are various types available. FK Moore is a long time supplier to the sign and display industry of both nylon and metal locators. Karen Jackson gives a few pointers on selecting the most appropriate product.

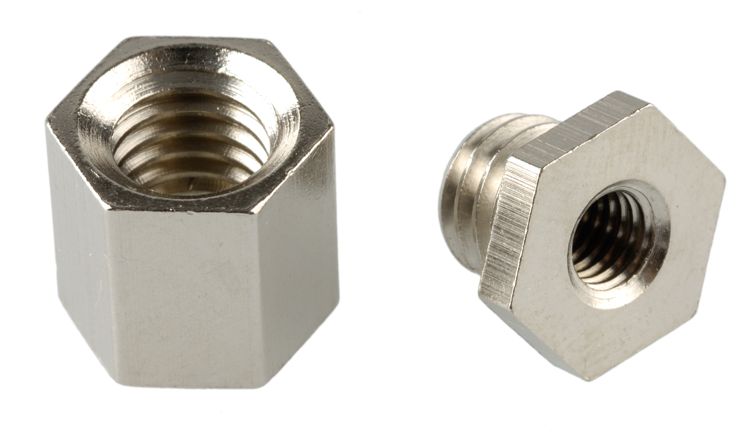

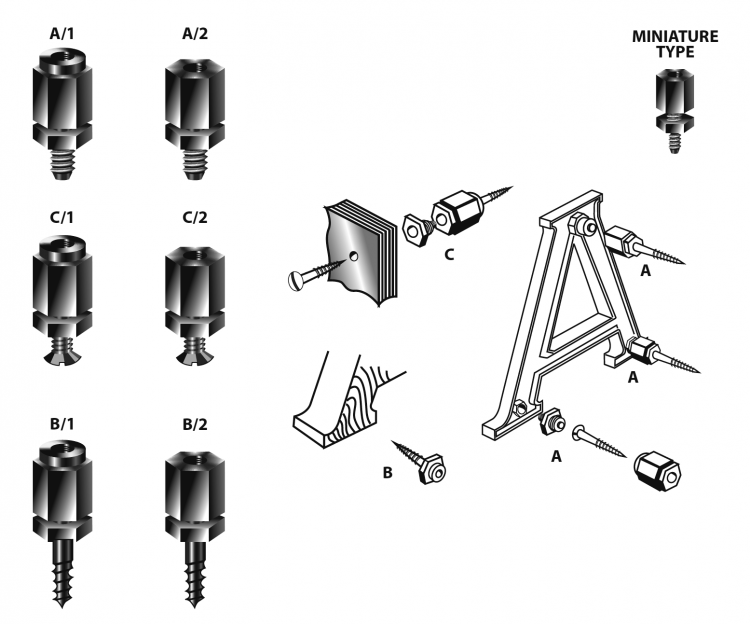

Fixings for metal letters can be offered in large or medium sizes with three options available on the male part. Fixed stud is supplied in either M4 or M5 thread; these would be screwed onto the back of the letter using a predrilled hole or insert. Then we have internally threaded fixings, also available in either M4 or M5 thread, with the option of being soldered or bonded onto the back of each letter, screwing onto studs that are already in place or using a screw through the front of the letter and screwing back into the male fixing. For smaller metal letters we offer a miniature locator fixing with either a fixed stud or internally threaded in M3 which work in the same way as the large or medium sizes and are available in either self-coloured brass or nickel-plated finish, depending on personal choice and aesthetics.

For wooden letters and fitments with wooden backing we suggest using a brass locator fixing with a fixed 8-gauge woodscrew on the male that will screw into the wood.

Fitting to the wall or support for end result

The male locator fixing is pointed in order for it to be used to mark accurately the positions on the wall (or other support) at which the corresponding female fixing are to be fixed. The female fixing is then screwed to the surface, enabling them to rotate on the screws and then tightened around the male locator fixing until secure, using a spanner. Available in either self-colour brass or nickel-plated finish (depending on personal choice and aesthetics) dimensions are as follows:

- large - overall length 17mm, width 12mm;

- medium - overall length 12mm, width 10mm;

- small - overall length 10mm, width 8mm.

In our experience, nothing beats a metal locator for strength, longevity, security, value for money and ease of maintenance.

Nylon locators:

Nylon locators are suitable for use with acrylic, ACM and foam on smooth, reasonably flat surfaces; these are perfect for both internal and external use as they are UV stabilised and frost-resistant. Although nylon are used externally, we would always recommend a mechanical fixing (metal locator) as offers more strength and longetivity.

These are available in black and white cups as standard in four sizes:

- mini with stud diameter of 8mm and overall length including socket of 12.4mm

- small with stud diameter of 12.5mm and overall length including socket of 19mm

- medium stud diameter is 16.5mm with overall length including socket of 19.9mm

- large size has a stud diameter of 18.5mm and overall length including socket of 24mm

We recommend using Penloc VT Plus with the nylon locators, this is a toughened 1:1 ratio structural adhesive, formulated for bonding thermoplastics, metals and composites. The combination of minimal surface preparation (ie lightly abrade the surface before applying adhesive) and rapid fixture time, makes it ideal for a variety of assembly operations (working time 4-6 minutes, fixture time 10-12 minutes) always follow these bonding guidelines. A word of caution: never over-tighten screw in female part; to avoid failure, allow for expansion. Finally, never use our nylon locators with any other manufacturers’ brand as they will fail as the parts can differ in size and dimensions.