A different way to make built-up letters using your CNC router

The first impression of a property or organisation is the external signs and built-up letters can offer high visibility and create a lasting impression. Liam Hodson, tooling & machine consultant, LKH Tools, outlines options for manufacturing the customer’s vision using the latest materials.

Typically, the traditional built-up letter method would require steel being formed around the letter and welded or soldered to the face. This has proven to be both labour and time intensive as in most cases, it would be done by hand (requiring a certain skill set). Smaller letters are usually very intricate to form around and, lower case letters for example, require a high degree of expertise to achieve the desired and consistent results.

Solid material

Automated machines are available for forming the return but still require the skills for welding (or soldering) everything together. In some cases, the alternative is to manufacture the sign out of solid material. This removes the need for welding or soldering and hand fabrication but allows for further creativity in the materials and colour choices used.

CNC router tooling provides the option for solid materials of up to 20mm to 30mm thick to be routed but still retain a small radius in the corners. For larger letters, a thickness of up to 40mm can be achieved with a 3mm internal radius and 55mm with a 5mm internal radius. The introduction of balanced 12mm, 22mm, 32mm, 42mm and 55mm lengths of cut routing tools from Crown Norge, available in the UK from LKH precision tools, has given sign makers even more flexibility to meet the customers’ demands.

A popular material choice for this is acrylic; however, aluminium, brass, PVC and sign foams can be used. Less dense materials will allow for a lighter sign but may not be as durable. Dry routing of up to 30mm aluminium and brass is now possible with the MP Superior tool and 55mm in PVC foams with the MP tool range. This allows for a wider choice of multiple colours or material combinations to achieve even greater impact.

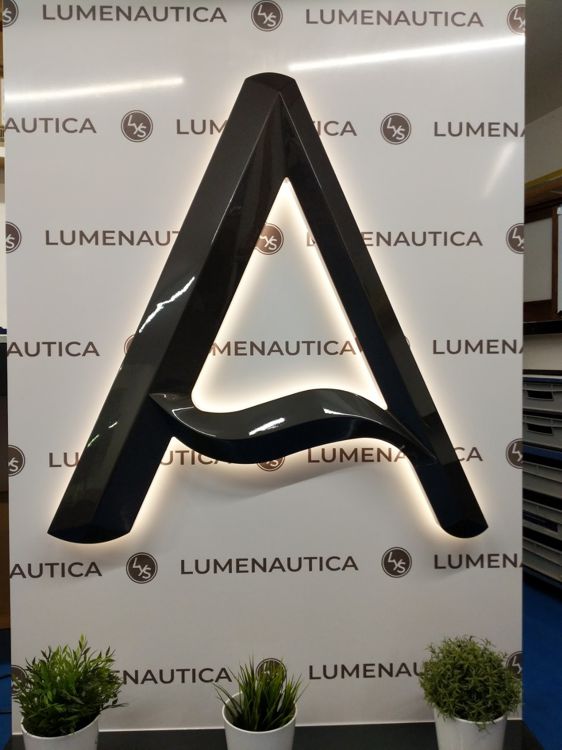

One advantage of cutting the letter complete with the same machine is the accuracy achieved. The face and return will match perfectly, which is particularly important if the intention is to backlight the letter. This eliminates light leakage as the precision cut parts will fit without gaps. It is delivered partly by the machine, but also the consistency and precision of the tools available in our range.

Routed channels and holes drilled for mounting LEDs can be introduced to provide positional accuracy. This will give a balanced and more consistent light in the desired areas.

Profiled edge

For a shaped or profiled edge, the negative radius or the round and route tool provides a simple way of putting a shaped edge to the letter. This would not easily be possible on a traditional steel faced welded letter and the end result gives a moulded or formed effect to the edges.

The V-shaped 3D tools in the range can be used to create a bevel to the letter. This can be combined with the correct software to create a carved effect and sharpen the internal corners due to the tool having a point at the very tip.

Not limited to wood and sign foam, these tools can be used on acrylic and PVC materials. Clear acrylics can be used to good affect when light is to be projected from the side or behind the letter.

With the correct machine, the cut edge can be additionally polished with the MCD, CVD and PCD ranges of finishing tools. This operation (which is completed on the CNC router after the initial cut), can allow for free flowing of light through the edges. Although a high standard of finish can be achieved with the standard acrylic tools, the final polishing pass will allow light to pass through more evenly, with greater clarity. Polishing this way prevents heat cracking or edge deterioration as often seen on laser cut or flame polishing methods. This is very important, for example, if the acrylics are to be glued or built up in sections.

As the edges are perfectly vertical, it will make for a much easier and more accurate final assembly. In addition, a chamfered edge can be polished using the 45 degree MCD polishing tool.