In Focus: Built Up Lettering

Applelec fuse the latest technology in letter construction with the traditional skills of the company's letter fabrication team.

From a letter making machine which creates returns for built-up letters in seconds to the time honoured practices of metal letter workers hand finishing each letter individually, Applelec have a variety of systems in -place to maximise speed whilst delivering exceptional quality.

This combination of established and innovative techniques creates an adaptable and efficient letter making environment to suit the needs of Applelec's customers who may require fully fabricated signage solutions featuring built-up letters or simply the raw letter parts to finish in their own workshops. Indeed this part production of letters is proving to be a significant asset to a growing number of the UK's sign makers.

Andy Armitage, Applelec's Business Development Manager, explains: 'As our relationships with medium to large sign makers strengthen, we have found that in some cases we are only making the mill finish built-up letter for our customers to finish and assemble in-house. As built-up letters are labour intensive this can often allow our customers to free up the time of their letter making team or prevent a bottle neck in their own plant or factory.' With their production staff free to concentrate on in-house production specialities, sign makers are then able to take on additional work, knowing elements of the letter construction can be accommodated at Applelec. Andy Armitage continues: "Of course our core offering is still needs of customers, each with their own unique set of requirements."

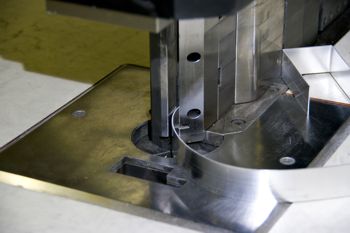

A key piece of machinery at the heart of Applelec's built-up letter production is an automated return shaper, a specialised piece of equipment which is located at the company's Leeds factory. The machine is programmed using vector artwork and can produce letters with a variety of return sizes ranging from 20mm to 120mm.

Requiring a single technician to operate it, the machine is fed with coiled metal in stainless steel and aluminium. Andy Armitage says: "Unlike a digital printer or plotter you cannot simply press go and wait for the finished product. The operator needs to be fully conversant with the letter building techniques. The time savings however are well worth the investment as returns are shaped with precision and accuracy in a fraction of the time"

The machine is particularly efficient when multiple letter sizes are required for a cohesive project or roll out. Indeed, the automated machinery is already utilised in several national roll outs with internationally known brands. Once the returns have been shaped, they are hand assembled with a metal letter face and can be delivered at this stage or finished according to specification with paint processes or the addition of LED illumination.

Of course not all letters are created in-house at Applelec with premium finish letters an example of the diverse range of lettering products available from the company. The premium range letters can be produced to sizes as small as 50mm in height with 6mm returns and with small stroke widths. The fully blended edges eliminate all sharp points to create a touchable smooth finish which typifies the superior quality of these letters. Along with the standardised metals routinely selected for built-up letters, the premium range can be created in unusual materials including brass, copper and black titanium or with distinct effects such as verdigris. For exterior applications, titanium letters offer a striking alternative to brass.

Andy Armitage states: "The premium range of letters has to be seen to be believed, the quality and craftsmanship exceeds anything that can be manufactured in the UK. The letters are particularly effective when used for eye level signage as seen in the receptions of law firms and architectural practices where the detailing of the letters can be appreciated." As Applelec approaches its 15 year anniversary in 2013, it is hoped that by continuing to improve procedures and by bringing exciting new products to market, the company will continue to offer customers a valued service as a confidential trade supplier to the thriving UK sign industry.

For more information about Applelec's Built Up Lettering services please visit www.applelecsign.co.uk or call 01274 774 477/ 01442 500 050.