V-grooved, folded edges on Aluminium Composite

- Written by Martin Hinchliffe

- Hand held router

- Aluminium ruler with a steel edge

- Stanley knife

Aluminium Composite is the only sheet material I tend to stock in several colours, and is my sheet material of choice, because it is so easy to work with. But getting a good enough edge can be a problem!

One of the things that I struggled with at first was cutting it. But I have really got to grips with it to produce a nice finish.

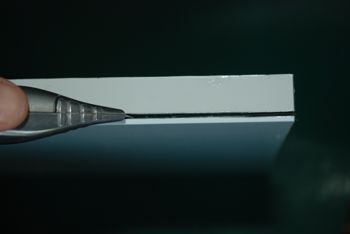

The best tip I have learnt up until now is to snap the ACM. To do this, you cut through aluminium skin and half way into the PE core, then snap it off. The edge that is snapped off will have a good edge, but the other side will have a bit of a lip on it as the blade separates the aluminium. So when you start always cut into the no-facing side.

Another piece of advice I got about a year ago, and then came across it again recently, is to v-groove the ACM with a hand held router and then fold it back on itself, and remove the excess.

There are two variations for this. I struggled with the method on the right hand side, as this meant folding the ACM in a small z-shape. But in theory you should be able to snap off the excess and get a better edge.

- V-groove and then cut where the blue line is at the edge of the v-groove. This cut should ideally be all the way through the PE core, and possibly further to score the final layer of aluminium. Following the left, you don't need to cut so deep with the blade, and then you just keep folding it back on itself which was easier to do. And I used a blade to help the excess break off. On the right hand side you need to cut even deeper all the way through the PE core, and ideally further to score the final layer of aluminium.

- Fold along the v-groove.

- Snap off the excess. Following the left hand side I needed a blade to help cut-off the excess.

In doing this research and talking to a few sign-makers, I have heard that you can get ACM with a transparent PE core. Although never bought any yet, this sounds like a really good option. It would eliminate the black edges on white sheets, which really stand out like a 'sore thumb', and make the requirement for this technique less important.

Will I be doing this on all my ACM sheets?

My router is set up with the v-groove permanently ready to do this, which reduces my set up time. But it still takes a little while to do. I need a proper work bench, so until I do I think I will just do this on the smaller panels that are looked at quite closely and that are at eye height.

If I had the height, I would probably get a Sagetech vertical panel saw, which would then give me a nice edge from the start.

I think in future, I will have a go doing it with the technique on the right hand side as should give a better finish.

If you have any feed back on this technique or any other tips you would like to recommend, I would love to hear from you. Phone, visit us at Sign & Digital UK (M37) or email me on martin@signupdate.co.uk