Interview: Trade Etching Direct

We spoke to Anthony Dullaghan, Managing Director of Trade Etching Direct, who shares his expert views and opinions on why sign makers should consider Etching as a way of increasing their revenue.

What is your background?

I started work for the family business, Masteretch Services, fourteen years ago. Masteretch manufacture etching equipment for a variety of industries and my job function was to work in the R&D department working on developing processes for customers around the world. The job involved travelling to meet customers both in the UK and the USA. After leaving Masteretch I worked for a leading company in the etched sign business for two years before starting my own company Trade Etching Direct. I realised there was a opportunity for a company to offer a first class service to the etching industry and my previous experience has put me in an excellent position to do this.

What is the difference between Etching and Engraving?

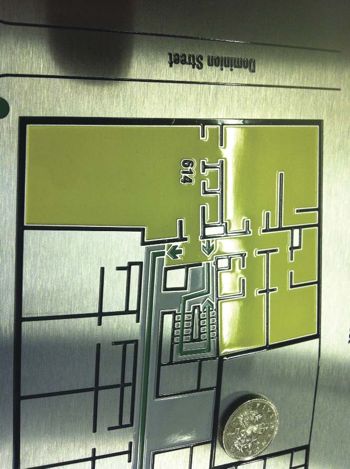

With engraving the engraver has to cut each individual word and also, with stainless steel, pay attention to keeping the tools sharp etc. This is time consuming and makes very detailed work difficult. With etching, a photosensitive film allows us to etch any image that can be printed as artwork and as the plate is etched with a high pressure acid spray the amount of detail does not affect the etch time.

What kind of research have you been involved in?

A wide variety of projects for sign, automotive, aerospace, medical, lighting companies and these include:

- Embossing dies for laminate flooring

- Stainless steel gobos for projected signs ( this is a service we will shortly be offering at TED)

- Etching of amputation tools for a surgical instruments company

- Heating elements for airframes to ensure that ice does not build up on wings etc.

- Etching of Dichroic filters used in stage lighting

- Steel pad printing clichés for high volume pad printing of ceramic transfers

- Developing a 'lathe' etcher for etching cylinders used in printing

- Magnesium and Zinc etching systems for hot foil stamping

Do you feel that Etching is a viable added revenue stream for enterprising sign makers? Why?

A wide variety of outdoor signage is produced in stainless steel, brass etc. and offering this service is easy for sign companies because it does not involve capital investment - they merely produce the artwork and email it to an etching company who do the rest.

Clearly it is essential to hook up with an etching company who can do a fast service, offer a first class product and most importantly set the price at a rate that allows a trade customer to make a good margin - all of these things are available with Trade Etching Direct. We want to develop long term relationships with customers who will come to think of us as 'their own etching department'.

What are your top 5 tips for sign makers who want to get involved in Etching?

- Hook up with an etching company who can offer a fast 'trade' service

- The price should allow the sign maker to build in a decent profit margin

- The quality should be first class and a no quibble guarantee that anything that is not perfect is put right

- Look for new business outside the traditional sign makers market - engineering companies who require rating plates for equipment , elevator signage, consider offering the projected signs available from TED

- Remember that this is an opportunity to increase your turnover without any capital investment

For more information please email tradeetching@gmail.com or call 01536 203 813 to speak to Anthony.