Multitechnic invest for efficiency

Chemical etching specialists Multitechnic Ltd have taken delivery of two custom built etching machines to further improve their efficiency. The installation has also involved a complete refit with the etching area stripped right back to bare walls and even a new concrete floor with improved drainage systems.

Chemical etching specialists Multitechnic Ltd have taken delivery of two custom built etching machines to further improve their efficiency. The installation has also involved a complete refit with the etching area stripped right back to bare walls and even a new concrete floor with improved drainage systems.

Multitechnic will now have five machines operating, all dedicated to optimise the requirements for different materials and methods of etching so that a wide mix of jobs can be processed at all times. This will improve turnaround times even further as there will always be a machine ready for any job that is required.

Managing Director, Colin Edge says, efficiency is key to improved performance. "Customers will no longer tolerate delivery times measured in weeks, quick response is everything. A simple job of just a few signs should be in and out in a couple of days, our customers have better things to do than chase suppliers for deliveries."

The machines have been built by Northampton based Cirgraphics following the successful long term testing of a prototype. Cirgraphics have previously supplied equipment to Multitechnic and were chosen for their high quality and no nonsense approach to equipment design and manufacture. They are based upon one of the oldest types of etching machine, but also one of the best for very fine detail.

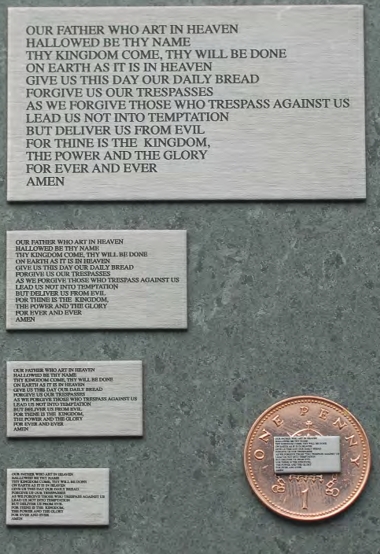

As Colin explains, fine detail is everything in the world of chemical etching. "Basic signs can be churned out on crude machines, but add a small and complex logo or a photograph to the design and you need the right processes to get the right result. When showing examples of our work to new customers we get the same comments every time, they are amazed at the clarity of detail. People are more aware of quality of graphics these days, and if you present them with a sign where their logo is just a blurred splodge they will not be very impressed."

The choice of such simple machines was based on years of experience encompassing every type of etching machine. "The technology to create the image on the metal is the clever part, for the actual etching you just need to get the sign in and out of the machine as quickly and cleanly as possible, something you simply cannot do on most etching machines as they have been designed to suit making printed circuit boards, not signs," says Colin.

The choice of such simple machines was based on years of experience encompassing every type of etching machine. "The technology to create the image on the metal is the clever part, for the actual etching you just need to get the sign in and out of the machine as quickly and cleanly as possible, something you simply cannot do on most etching machines as they have been designed to suit making printed circuit boards, not signs," says Colin.

The refit of the etching area was carefully timed to minimise disruption and to coincide with a traditionally quiet time of the year at the beginning of the school summer holidays. The sign industry however, has a sense of humour and on the very day that the builders moved in, a customer landed a whole hotel's worth of signs in the inbox. Despite being reduced to one etching machine in a storage shed, the job was completed ahead of schedule, and not a single job was delayed.

For further information contact Multitechnic on tel: 01670 512090 or visit the website www.multitechnic.co.uk