Built up letters - How do they do that?

Built up letters are everywhere, we take them for granted, but making them is one of the most skilful trades in the sign industry. Kevin Washbourne of Impact 3D Signs Ltd explains how it is done.

Built up letters are everywhere, we take them for granted, but making them is one of the most skilful trades in the sign industry. Kevin Washbourne of Impact 3D Signs Ltd explains how it is done.

Stainless steel is the most popular material for built up letters, although other metals such as brass, copper, even plastics such as acrylic can be made in basically the same way. They are all made with a flat cut face with a return fabricated to follow the outline which is attached to the face.

Like just about everything in the sign industry these days, the first stage is when we receive digital artwork by email. This is used to make a flat cut face, mostly by laser cutting but we sometimes still use the traditional method of tracing out & cutting by eye with a bandsaw. For a very urgent job it can still be quicker to cut this way than you can say DXF file. The stainless steel is always 316 grade as these signs are nearly always used externally and are never cleaned, inferior grades discolour & look shabby very quickly.

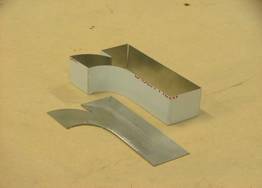

Strips of the same material are accurately cut on the guillotine to the required width of the returns. The flat cut out letters are carefully inspected & dressed to remove any burrs. A piece of wire is bent to follow the shape around the letter, this way the length of strip to make the return can be measured and cut.

Every letter or shape has a starting point, usually at the top so that the joint will not be seen. The strip of metal is aligned with this point, and the position first bend is marked by eye where it will be curved or folded to give the right shape, flush to the edge of the flat cut letter. It takes a lot of experience to get this right, even a small error will result in an unsightly overhang or incorrect fit. A set square is used to mark the line across the width of the strip.

The strip is taken to a folding machine and is folded to the right angle, again by eye. If a curve is required rather than a fold, this is done by hand, or for larger lengths of curve using rollers. The strip is taken back to the flat cut letter, checked for a good fit, then the position for the next fold or curve marked by eye. This continues until a complete outline of the letter is made, any spare material being trimmed off to make a neat joint at the starting point.

The next stage is to solder the two parts together. We may use laser technology for most of the cutting these days, but soldering is still done using old fashioned soldering irons, which are actually made of copper, and are heated in a gas flame to just the right temperature. Too hot and the solder will not stick, too cold and the iron will not have enough heat to melt the solder onto both faces of the letter. I always like to have a few irons in the fire!!!

A brush is used to apply flux to the edge of the return and the back of the cut out letter. Care is taken to keep the flux off the face of the letter or it will leave a mark. The two parts of the letter are then held in position by hand. The hot iron is dipped in a solution to remove impurities then is held against the joint to be soldered, solder being applied to melt onto both faces and make a secure join. When the iron starts to cool it is returned to the fire and another used to continue until the whole return is neatly joined to the face.

Finally the join where the ends meet is soldered, and if required, studs or other fixings are soldered in place. The letter is dipped in water to remove any flux, then cleaned and carefully inspected.

That is the process for simple built up letters, LEDs can be attached inside the letters, pack them up and send to the customer.

There are much cleverer things than simple flat letters with flat returns. We can make returns with bevels, double bevels, all sorts of profiles. The same methods can be used to make light boxes and logos with illuminated faces. We can use aluminium with MIG or TIG welded returns and powder coat paint, stove enamel, or use coloured stainless steel for vibrant metallic colours.

Various examples of lettering:

When we have finished making these clever signs at the end of the day, I can go home, clean up, have a quick bite to eat, then appear on a stage near you as Kevin Starr, the legendary stage hypnotist.

For further information contact: Kevin Washbourne, impact 3d Signs Ltd, Tel 01915 360536 or visit www.impact3dsigns.co.uk