The Channel Letter Bender

The Accu Clinch

- Assemble: Built to quickly and easily fasten aluminum or light steel parts together, the Accu-Clinch is the fastest way to assemble metal components to create a completed channel letter. With the Accu-Clinch, your operators can attach a back to your channel letters in a matter of minutes.

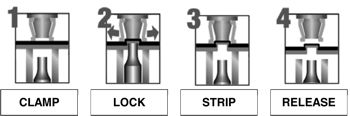

- Pressing: The Accu-Clinch uses a bottom punch and top die to press-form two pieces of material together without rivets, staples or stitches, cutting the cost of consumables

- Job right: Cut the high cost of labor and consumables, and get the job done right with an Accu-Clinch.

More and more businesses are choosing to invest in a channel letter bender, which are still relatively new and being judged on its productivity versus the high costs. From talking to various sign makers, there are models available from America, South Korea, China and Poland. Selling American made machines in Europe is The Channel Letter Bender who say they first launched the Accu-bend 20 years ago.

Remko van Gellecum, from the company, said: "Our clients' return on investment speaks for itself. Accu-Bend reduces labour intensive hand fabrication, resulting in increased capacity and more revenue. With hundreds of Accu-Bend machines around the world, The Channel Letter Bender is recognised by the largest sign makers as the right choice for reliable, quality machines that save time and money. Made with a heavy steel-welded frame, these U.S.-manufactured machines are built to last. Made with top-quality components, high-grade materials and the latest technology, Accu-Bend continues to set the industry standard."

He said: "The Accu-Bend machine is the only machine in the world to notch, flange and bend the complete channel letter. Also if you manufacture welded letters, our machine will also bend those letters for you. The Accu-Bend can also bend every vector line of the most complicated letters identically. By hand you could not even bend two the same. The slight differences would cause you to create different letter faces matched to only fit one letter. In the future letters that need to be fixed can be done from the same computer file, you do not have to trace the letter and match it by hand."

Other machines in their range are the Accu-Bend Lite, the Accu-Clinch, the Accu-Cut and the Channelletter Former. The Channelletter Former produces channel letter faces, push through letters, moulded letters, and thermal-form signs and parts. The Accu-Clinch uses air-over-hydraulic power to attach aluminium backs to the side wall return. It does a quick 40 clinches per minute. The company claims it is the fastest way to assemble metal components to create a completed channel letter.

Features of the Accu-BendA complete computer system and swivel monitor comprise the control centre of the system. Simply import .DXF files, and your channel letters are created.

After installation and a short training session, most companies are able to run the full production the first day.

A dedicated hydraulic power system and dual-motor drive unit have extensive power and can feed up to 30 cm per second.

The Accu-Bend is easy to modify for any project. Operators can change coil heights in less than two minutes. The system can also accommodate a width or depth of channel letter coil between 2,5 cm and 24 cm.

Can handle aluminium up to 1,5mm thick and stainless steel up to 1 mm thick.

The optional Robotic Auto Pilot allows the machine to run multiple letters, unmanned, so you save on labour costs. The system completes letters, pulls them from the machine and starts again.

Should you need help operating or maintaining the support is available for as long as you own the machine.