Keep all your “soldering” irons in one fire

Since inception in 1974, Sygnet Signs has been dedicated to becoming the most innovative, all encompassing and complete trade sign manufacture nationwide.

Originally formed in 1974 by Mick Iley and now under the leadership of his son Gary, Sygnet Signs has spent the last 42 years servicing the industry, meeting client objectives and providing the finest signage solutions to meet all requirements. “We aim to provide a wide range of solutions, whether that be a set of flat cut acrylic letters, or the most complicated of totem signs,” says Ross Martin, Department Head at Sygnet Signs, and an employee for 14 years to date. Sygnet Signs offer solutions to any 3D built-up letters, and can produce products such as flat faced letters, trough letters rim and return letters or rimless letters from stainless steel, mild steel, aluminium, copper and brass.

Sygnet Signs acknowledged there was a need to extend its services in order to maintain growth and widen its client market in 1995, when they caught wind of a rapidly increasing demand for the trade manufacturer to supply “the whole signage package”. Recognising the need to evolve, management started investigating the market of built up, three-dimensional letters. “An investment was made, and we purchased our first flatbed laser, a real rarity for a trade sign manufacturer at the time,” says Ross. “This meant that Sygnet were now in a position to be able to laser cut all stainless steel letter faces in house, completing the build in our newly formed letter shop department. This investment proved pivotal, and profitable.”

Starting out in 3D lettering

It wasn’t long before the manufacture of built up letters became staple diet for Sygnet, and this is something that remains the case today.

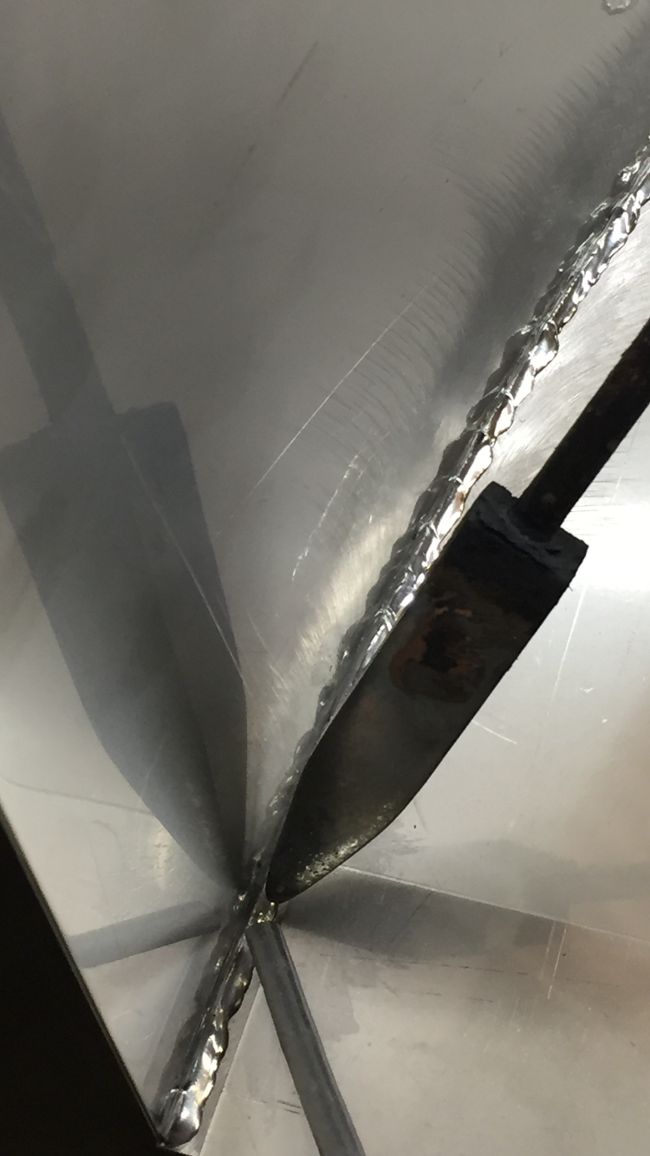

Whilst the technological world continues to develop new exciting systems and materials, Sygnet’s letter shop still operates in a way very similar to how it did in 1995. Highly skilled letter shop operatives, who have honed this art form down to a tee, manufacture the bulk of the work by hand. “Not only are our letter shop staff time efficient, but the quality of their hand crafted, fully soldered letters is unrivalled across the industry. It’s safe to say, that no matter the size of your project, with the wealth of experience their letter shop has, you’re in very safe hands,” adds Ross.

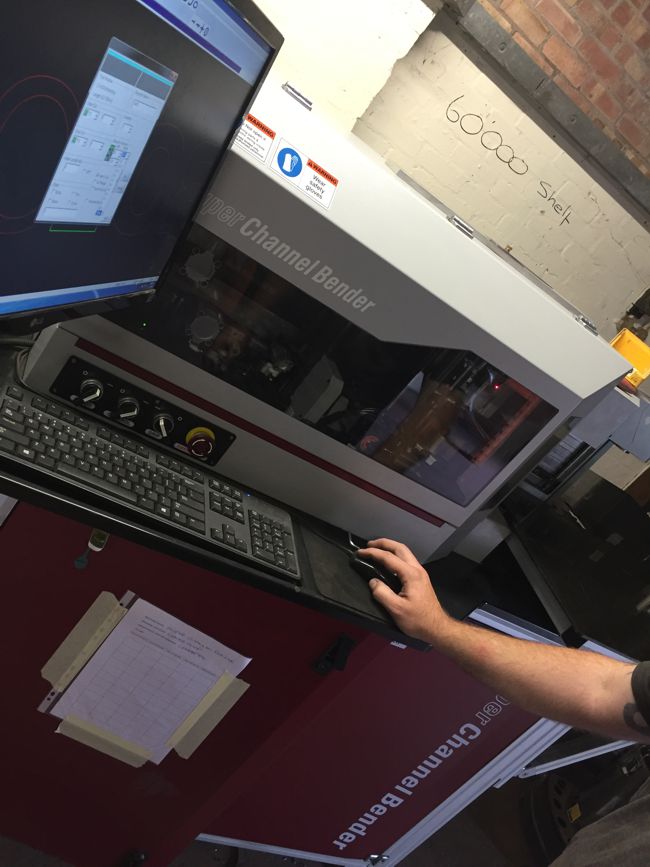

Whilst building letters the traditional way may offer a nostalgia and reliability, it doesn’t mean that Sygnet Signs haven’t continued to invest to keep up with the leading pack. Having noticed an uptick in the number of enquiries for large nationwide roll-out jobs, it became apparent that they needed to explore new avenues. Following an abundance of research, Sygnet invested £60,000 in a market leading channel bender. This piece of machinery sets the company up perfectly for roll out projects and bulk orders, as it offers the ability to press through substantial volumes of work quickly and on budget, whilst retaining a precise finish to the completed article. ‘The introduction of the letter bender will prove invaluable,” says Ross. “It is a cracking piece of kit, and will come into its own when we take on large roll out and repeat work contracts. It gives us the opportunity to become much more cost effective and competitive when tendering for those larger contracts.”

While Sygnet fully appreciates the introduction of such pieces of machinery, Ross is quick to add that having a team of skilled operatives to use it is invaluable, and that this machinery is no substitute for hand-craftsmanship when creating built-up letters. “The collective experience we have is crucial,” he says. “The channel bender is perfect for what it’s designed for – bulk work.

We understand not all of our work is going to form part of a nationwide roll out, and so the one off, bespoke projects are still all manufactured by hand and that suits everybody. We pride ourselves on the quality of our hand metal built letters, and of course, with so many variations and specifications to the letters we are able to build, some things have to be built the traditional way.”

Sygnet Signs is also able to supply LED products to illuminate these letters. Their sister company, LED Solutions, is the distributor for HiTech LED, an Italian module manufacturer. All LED modules are supplied with a five-year manufacturer’s warranty on light and power parts.